Email: fern@hotechmachinery.com Tel: +86 13622727078

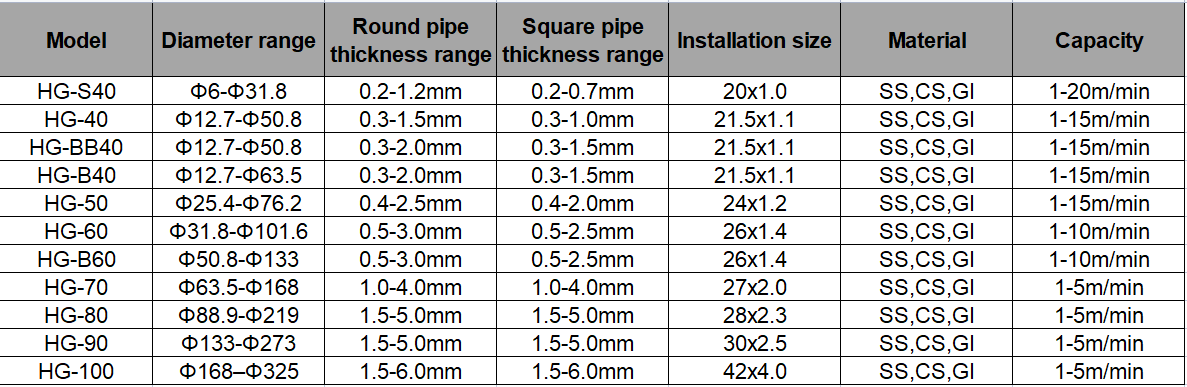

Big Size Pipe Making Machine is design to produce welded round tubes/square tubes,with diameter 100mm-500mm,thickness 1.0mm-10mm. The welded tube mill is newly design based on proactical producing and acquiring the advantages of equipment Taiwan design, which is also convenient in operation and maintenance. Brand: HOTECH Payment:T/T, L/C at sight Product Origin: Foshan, China Lead Time:60 days

The versatility of our tube mill machine knows no bounds, working effortlessly with various materials like stainless steel (316, 304) as well as materials such as Q235, 202, and more. Utilizing a W forming technique, this welded tube mill excels in welding sections, ensuring seamless pipe creation.

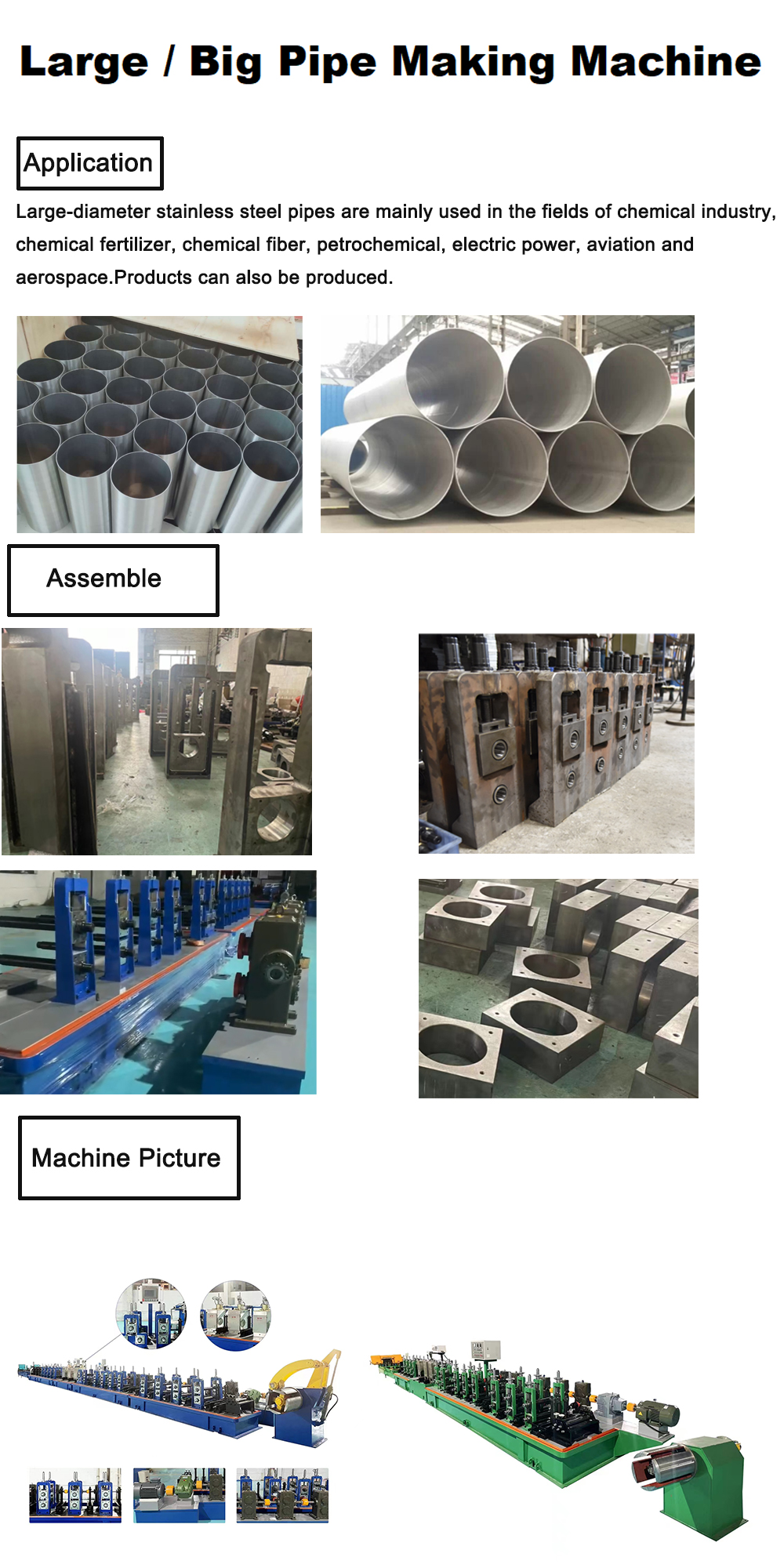

Compared to cast iron drainage pipes, galvanized steel pipes, or plastic hoses, our large-diameter stainless steel welded pipes exhibit exceptional superiority. Their application extends beyond industrial water treatment to encompass a broad spectrum of industries, including food, where maintaining high sanitation and safety standards is imperative. Our sanitation grade or antibacterial grade stainless steel welded pipes produced by pipe roll forming machine are the preferred choice for food transportation pipelines.

◆ Petroleum & Fertilizer Industries: Fulfilling the colossal demand for large-diameter stainless steel welded pipes used in furnace bodies, raw material delivery, and heat exchange systems.

◆ Water Treatment: Offering unparalleled corrosion resistance for water supply systems, surpassing alternatives like cast iron, galvanized steel, and plastic pipes. Ideal for industrial water treatment, purification, and seawater desalination.

◆ Food Industry: Meeting the stringent standards of material health and safety for food transportation pipelines with sanitation or antibacterial grade stainless steel welded pipes.

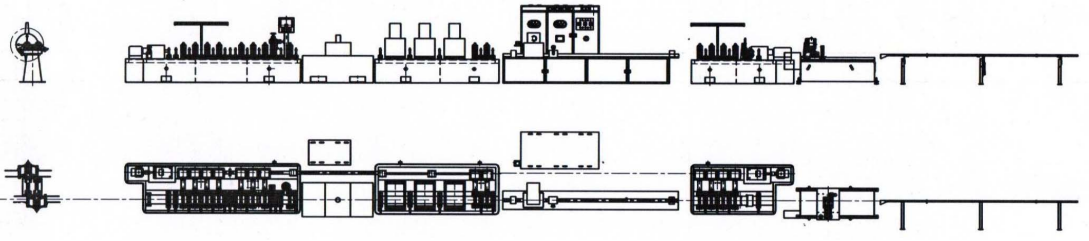

Machine Processing: Un-coiler→ Forming Section→ Welding Section→ Grinding Section→ Sizing & Straightening Section→ Cutting Section→ Run out table

| Machine Paramter | |

| Major motor | Siemens |

| Reducer | NJ130 or Dongfeng 145 |

| Cutting machine | Abrasive Cutting Machine or Metal saw cutting machine |

| Welding device | Included |

| Machine base | Q235 materials |

| Machine shaft | 40Cr |

| Machine arrangement | 3-3-1-4 or 4-4-1-4 |

| Customized Design | |

| PLC control system | Optional |

| Roller bearing standd design | Optional |

| Grinding section | Manual / Semi-automatic / Fully automatic |

| Double Motor | Optional |

| PLC control cutting machine-cut short pipe below 1 meter | Optional |

| Double acting system | Optional |

| Online inside bead rolling machine | Optional |

| Online bright annealing machine | Optional |

| After Sale Service | |

| Warranty time | 1 year |

| Installation service | 15 years experience engineer base on salary |

| Factory layout drawing | Provide |

| Return visit service | 2-3 times per month |

| Field visit service | 2-3 times for mature market |

The whole steel tube mills are welded by Q235 steel plate, world's top five hundred BAOSTEEL material, machine vibration aging treatment.

Follow Taiwan technology, provide stable structure design.

All the key parts are processed by CNC machine centre to ensure the precision of tube mills.

Adopt NJ130/Dong Feng auto transmission, enhanced turbine gearboxes, ensure stability of transmission system.

Pipe forming machine can be customized by customer's requirements.

Tube mirror polishing machines utilize a combina

Tube forming machines are essential equipment in

Seamless pipe is manufactured by extruding the m

Contact: Fern Li

Phone: +86 13622727078

Tel: +86 13622727078

Email: fern@hotechmachinery.com

Add: Shishan Town,Nanhai District,Foshan City,Guangdong Province,China

We chat